How Can Container Surfaces Stay Durable for 10+ Years? The Secret Behind Container Surface Treatment Revealed!

Currently, over 90% of global containers are manufactured in China, and these containers consume nearly 200,000 tons of coating materials annually.

Container Coating System

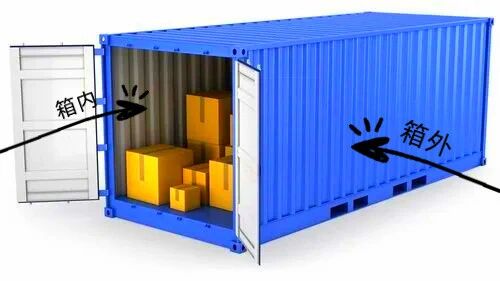

Generally, container coatings are divided into internal and external systems, which also vary depending on different transportation scenarios.

Exterior of Container

Due to constant outdoor exposure to sun and rain, the coating is required to possess high corrosion resistance.

Interior of Container

The sealed environment is prone to moisture, leading to rust, thus requiring coatings with high anti-corrosion properties; for containers transporting goods like food and pharmaceuticals, the coatings must also meet the biosafety standards of the cargo.

Internal Corrosion of Container

Green Container Initiative

However, traditional container coatings are mostly solvent-based, generating significant "three wastes" during spraying. According to incomplete statistics, solvent-based spraying alone emits an average of several hundred thousand tons of VOCs annually, causing severe environmental impact. Thus, a "Green Container Initiative" is quietly emerging.

Among various coating materials, powder coatings are increasingly gaining recognition and preference from container manufacturers due to their eco-friendliness, rich color options, easy application, and excellent performance. Today, powder coatings are gradually replacing solvent-based coatings, becoming a key material for container surface treatment.

As a professional powder coating manufacturer, JIADUOCAI Powder Coatings has always been committed to providing customized coating solutions for products across various industries, and the container sector is no exception. We offer specialized powder coatings for both outdoor and indoor applications, delivering one-stop solutions for containers.

Outdoor-Specific Powder Coatings

JIADUOCAI Outdoor-Specific Powder Coatings include Series A* and S* products, which comply with HG/T 2006-2006, GB/T 5237.4, and Qualicoat standards, making them suitable for outdoor applications.

Series A* powder is formulated using construction-grade polyester resins and corresponding curing agents as the primary raw materials; it offers excellent resistance to sunlight, rain/dew exposure, and heat.

Series S* is formulated using super-weatherable polyester resins and corresponding curing agents as the primary raw materials. With higher crosslinking density than Series A*, it offers a 10-year outdoor use guarantee.

Indoor-Specific Powder Coatings

JIADUOCAI Indoor-Specific Powder Coatings are formulated using epoxy and polyester resins as the primary raw materials. They combine the unique properties of both epoxy and polyester, providing the coating with excellent decorative appeal, anti-yellowing properties, mechanical performance, and strong corrosion resistance, complying with HG/T 2006-2006 thermosetting powder coating requirements.

Established in 2002, JIADUOCAI Powder Coatings possesses over 20 years of powder coating formulation experience and a mature technical team. All types of powder coatings developed and produced by the company demonstrate exceptionally high first-pass transfer efficiency, ensuring long-lasting, stable results and highly smooth film formation on large flat surfaces. In the current era of green environmental protection, we actively respond to environmental initiatives by adopting eco-friendly materials and advanced production processes to reduce environmental impact, supporting the further development of green actions with high-quality products and services.